Many american manufacturers are surprised to learn that nearly 40 percent of all production downtime traces back to slow or ineffective support desk processes. For operations managers under pressure to cut costs and improve uptime, getting the support desk model right makes a measurable difference. This guide clarifies what truly defines a modern factory support desk, exposes common misconceptions, and shows how global firms gain an edge with streamlined, often outsourced, IT and service desk solutions.

Factory Support Desk Defined and Misconceptions

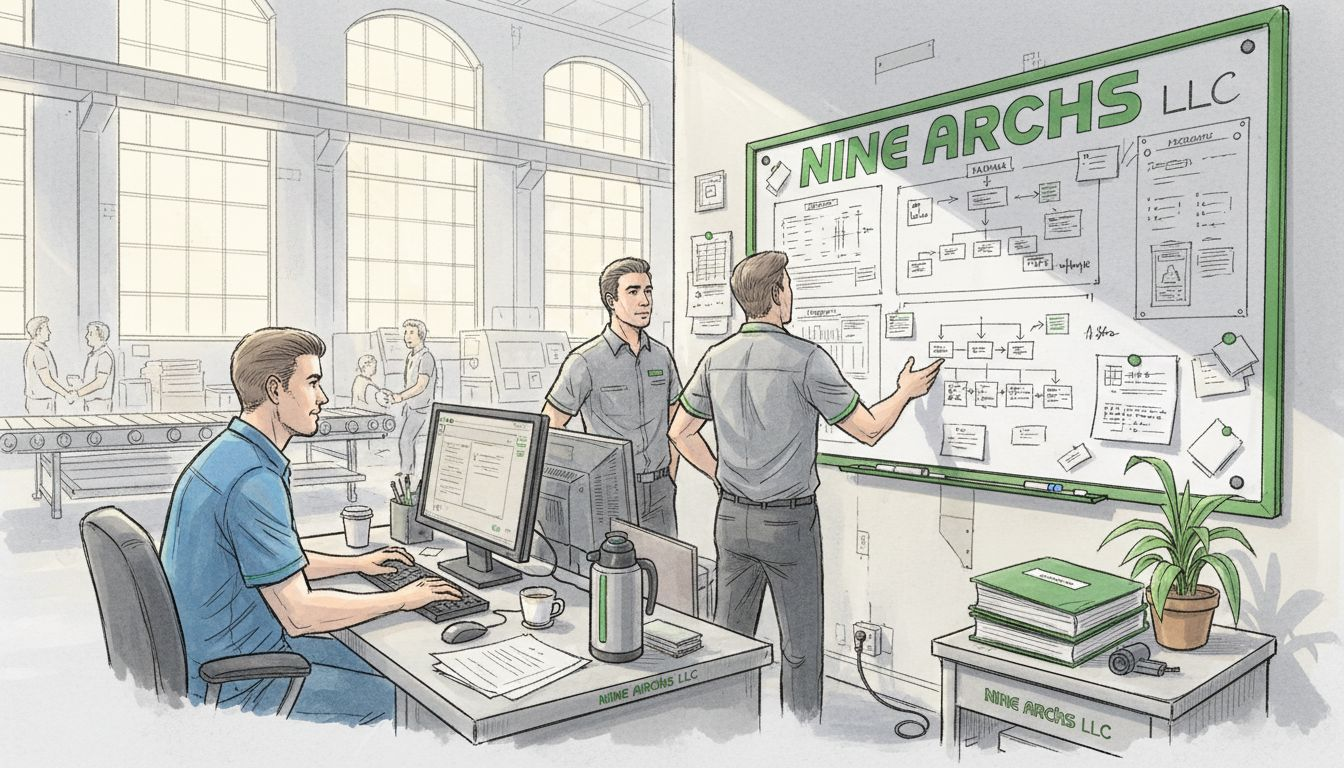

A factory support desk is a centralized operational hub designed to manage, coordinate, and resolve technical and process-related challenges within manufacturing environments. Unlike traditional IT help desks, these specialized units integrate deeply with production systems, providing real-time technical assistance and workflow optimization across complex industrial settings.

In modern manufacturing, support desks leverage advanced technologies like intelligent ticketing systems and automated communication platforms to streamline issue resolution. These systems allow rapid response to operational uncertainties by connecting employees with technical experts who can diagnose and address problems quickly. Key functions include monitoring production workflows, managing equipment maintenance requests, troubleshooting technical disruptions, and facilitating communication between different departments.

Common misconceptions about factory support desks often revolve around their perceived limitations. Many organizations mistakenly view these units as purely reactive entities that only respond to emergencies. However, contemporary support desks are proactive strategic partners in operational efficiency. They aggregate performance data, identify potential bottlenecks before they occur, and recommend process improvements that can significantly enhance manufacturing productivity.

Pro tip: Implement a comprehensive knowledge management system within your factory support desk to capture and share critical troubleshooting insights across your entire manufacturing ecosystem.

Types of Factory Support Desk Models

Factory support desk models represent sophisticated strategies for managing technical and operational challenges within manufacturing environments. Tiered Service Desk structures emerge as the most prevalent approach, strategically segmenting support levels to match issue complexity and optimize problem resolution efficiency.

These models typically encompass multiple support tiers with distinct responsibilities:

- Tier 0: Self-service digital platforms enabling employees to resolve basic issues independently

- Tier 1: Frontline support handling standard technical requests and initial diagnostics

- Tier 2: Advanced technical teams addressing more complex operational challenges

- Tier 3: Specialized expert groups managing intricate technical problems requiring deep system knowledge

Beyond traditional tiered approaches, manufacturers are increasingly adopting innovative support delegation strategies that emphasize collaborative problem solving. Swarming Service Desk models represent a cutting-edge alternative, where cross-functional teams work together to resolve issues without rigid escalation hierarchies. This approach reduces response times, promotes knowledge sharing, and breaks down departmental silos that traditionally impede efficient technical support.

Pro tip: Design your factory support desk model with flexible boundaries between tiers, allowing rapid knowledge transfer and preventing bottlenecks in complex technical resolution processes.

Here’s a comparison of factory support desk models and their operational strengths:

| Model Type | Response Time | Knowledge Sharing | Suitable For |

|---|---|---|---|

| Tiered Service Desk | Moderate | Structured by level | Large, complex factories |

| Swarming Service Desk | Rapid | Highly collaborative | Agile and adaptive teams |

| Hybrid Approaches | Variable | Customizable transfer | Dynamic manufacturing needs |

Core Functions in Manufacturing Operations

A factory support desk serves as the critical nerve center for manufacturing operations, integrating multiple essential functions that drive operational efficiency and technical reliability. These specialized units go far beyond traditional help desk roles, acting as strategic partners that connect technology, personnel, and production processes through comprehensive support mechanisms.

The core functions of a factory support desk encompass several key operational domains:

- Incident Management: Rapid diagnosis and resolution of technical disruptions

- Asset Tracking: Monitoring equipment status, maintenance schedules, and inventory levels

- Compliance Monitoring: Ensuring adherence to safety and regulatory standards

- Communication Coordination: Facilitating seamless information exchange between production, IT, and maintenance teams

Beyond immediate problem resolution, modern support desks leverage advanced support delegation strategies to transform raw operational data into actionable insights. By integrating sophisticated analytics and real-time monitoring tools, these units can predict potential equipment failures, optimize maintenance schedules, and proactively identify systemic inefficiencies that could impact manufacturing productivity. This predictive approach represents a significant evolution from reactive support models, enabling manufacturers to shift from emergency response to strategic operational optimization.

Pro tip: Implement a comprehensive knowledge management system that captures and standardizes troubleshooting insights, creating a living repository of technical expertise that can be accessed across all support tiers.

Technology and Workforce Requirements

The evolution of factory support desks demands a sophisticated blend of technological expertise and adaptive workforce skills, driven by the rapid digital transformation of manufacturing environments. Industry 4.0 has fundamentally reshaped the technological landscape, requiring professionals who can seamlessly navigate complex, interconnected systems and leverage advanced digital tools to optimize operational performance.

Key technological capabilities for modern factory support desk professionals include:

- Advanced Analytics: Proficiency in data interpretation and predictive modeling

- Cloud Computing: Understanding multi-platform infrastructure and remote management

- Artificial Intelligence: Knowledge of machine learning applications in operational support

- Internet of Things (IoT): Skills in managing interconnected sensor networks and real-time monitoring systems

The workforce transformation goes beyond technical skills, requiring professionals to develop comprehensive remote workforce strategies that integrate human expertise with emerging technologies. Successful support desk teams must now possess a hybrid skill set combining traditional technical troubleshooting with strategic problem-solving, communication agility, and continuous learning capabilities. This evolution demands organizations invest in robust reskilling programs, ensuring their workforce remains adaptable and technologically competent in an increasingly automated manufacturing landscape.

Pro tip: Develop a continuous learning roadmap that allocates at least 10% of work hours to technology training and skill development, ensuring your support desk team remains ahead of emerging industrial technology trends.

Key technology and workforce capabilities for effective factory support desks:

| Capability | Role in Support Desk | Business Impact |

|---|---|---|

| Advanced Analytics | Predict, diagnose disruptions | Minimizes downtime |

| Cloud Computing | Enables remote support access | Increases scalability |

| IoT Integration | Real-time equipment monitoring | Boosts productivity |

| Continuous Learning | Keeps skills up-to-date | Sustains innovation |

Outsourcing, Cost, and Risk Considerations

Outsourcing factory support desk operations represents a complex strategic decision that requires careful evaluation of potential financial benefits against inherent organizational risks. Cost optimization remains a primary driver, but manufacturers must look beyond immediate financial savings to understand the broader strategic implications of external service partnerships.

Key risk considerations for factory support desk outsourcing include:

- Data Security: Protecting sensitive manufacturing process information

- Service Continuity: Ensuring uninterrupted operational support

- Quality Control: Maintaining consistent performance standards

- Knowledge Retention: Preventing loss of critical institutional expertise

Manufacturers can mitigate potential risks by developing comprehensive outsourcing strategies that prioritize vendor alignment with organizational goals. Successful outsourcing requires establishing robust contractual frameworks, implementing rigorous performance monitoring mechanisms, and creating flexible engagement models that allow for rapid adaptation to changing technological and operational requirements. This approach transforms outsourcing from a simple cost-cutting exercise into a strategic partnership that enhances organizational agility and technological capabilities.

Pro tip: Conduct a comprehensive risk assessment and develop a detailed transition plan that includes clear performance metrics, data protection protocols, and exit strategies before finalizing any outsourcing agreement.

Elevate Your Factory Support Desk for Lasting Efficiency

The article highlights critical challenges in managing factory support desks such as reducing downtime, ensuring seamless communication, and adopting advanced support delegation strategies. If your manufacturing operations struggle with reactive troubleshooting or inefficient tiered support models preventing rapid issue resolution, adopting a scalable and tech-savvy remote workforce can transform your outcomes. At NineArchs LLC, we understand the need for a proactive, knowledge-driven factory support desk that integrates advanced analytics and continuous learning to boost productivity and minimize operational risks.

With our expertise in knowledge outsourcing and business process outsourcing, we provide flexible solutions designed to optimize your support desk workforce. Leveraging global talent and cutting-edge digital tools, we help you build specialized teams skilled in IoT monitoring, predictive maintenance, and real-time incident management. This approach breaks down silos and accelerates problem-solving while maintaining strict data security and compliance.

Get ahead of manufacturing disruptions today by partnering with us to enhance your factory support desk capabilities.

Discover how our tailored remote workforce solutions can help you transition from reactive to strategic operational support.

Start the journey toward a more efficient and agile operation now.

Transform your factory support desk by connecting with our experts at NineArchs Contact.

Ready to boost your manufacturing efficiency through innovative outsourcing and robust support desk strategies? Reach out to NineArchs LLC to explore customized solutions designed just for your evolving needs.

Frequently Asked Questions

What is a factory support desk?

A factory support desk is a centralized hub that manages and resolves technical and process-related challenges within manufacturing environments. It differs from traditional IT help desks by integrating deeply with production systems to provide real-time technical assistance and optimize workflows.

What are the primary functions of a factory support desk?

The core functions include incident management, asset tracking, compliance monitoring, and communication coordination. These functions ensure operational efficiency and support technical reliability across manufacturing processes.

How do tiered service desk models work in factory support?

Tiered service desk models segment support levels based on issue complexity. Typically, they include multiple tiers from Tier 0, which offers self-service solutions, to Tier 3, which provides specialized expert support for complex technical problems.

What are the benefits of outsourcing factory support desk operations?

Outsourcing can optimize costs and provide access to specialized expertise. However, it is important to consider potential risks such as data security, service continuity, and quality control. A comprehensive strategy is needed to ensure successful outsourcing and collaboration with external partners.

Recommended

- 7 Examples of Support Desk Services for Scaling Businesses | NineArchs

- Master the IT Support Delegation Process for Streamlined Results | NineArchs

- Role of Support Desk in Customer Experience Success | NineArchs

- 7 Essential Types of Support Desk Services for Businesses | NineArchs

- IT Support Benefits Explained: Value for Brisbane SMEs – IT Start